Make a concrete water fountain

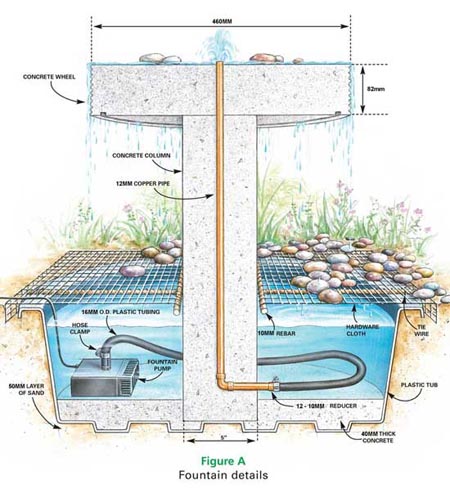

This little fountain, modelled after an old millstone, is the perfect size to tuck into a spot near your patio. There you can enjoy the sound of water trickling over river stones and watch the birds and butterflies that come to bathe and drink.

YOU WILL NEED:

1 bag cement

2 bagssand

Buckets of water

Wheelbarrow

Spade

Steel trowel

Plywood, 19mm for the formwork

Steel flashing, 100mm wide

Double-sided carpet tape

Ribbed foam (also used for packaging) - optional

Sheet metal screws

Round sheet metal duct cap and coupling

Length of 200mm round metal duct

Duct tape

Copper pipe, 12mm, elbow, and 12 to 10mm copper reducer

Two-part epoxy

Craft knife

Silicone sealer and caulking gun

10mm steel rebar

16-gauge wire

16mm O.D. plastic tubing

2 x hose clamps for above tubing

Pump

Galvanized hardware cloth

River rock to cover hardware cloth

Plastic tub

Construction adhesive

TOOLS:

Jigsaw, drill/driver, 16mm spade bit, hacksaw (or angle grinder),

HERE'S HOW:

To make the forms

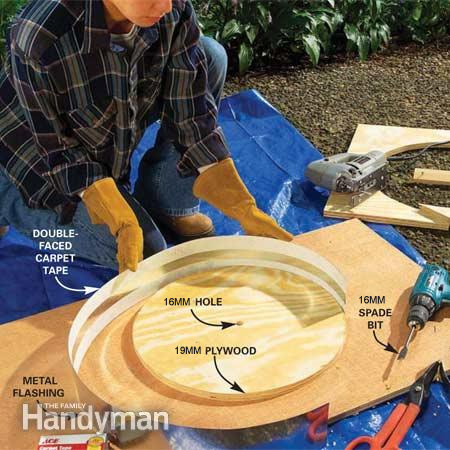

1. Draw a 460mm diameter circle on the plywood and cut out with a jigsaw. Drill a 16mm hole in the centre with the spade bit. On the steel flashing, run a strip of double-faced carpet tape along the top and bottom edge. Then wrap the flashing around the plywood circle.

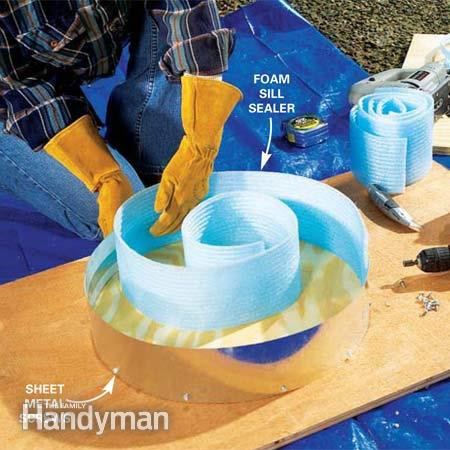

2. Drive sheet metal screws through the flashing at 200mm intervals to secure it to the plywood. Line the flashing with a length of ribbed foam (optional). To make a flush seam, cut through both thicknesses of foam where they overlap with a craft knife.

3. Insert a 100mm length of 12mm copper pipe into the hole and hold it in place with a wrap of bathroom caulk. Press a double-wide bead of caulk in a circle around the bottom of the form about 20mm away from the foam liner. Trim the foam flush with the top of the metal.

4. Cut a 500mm length of 200mm round metal duct with a tin snips. Cut the locking edge from the length of the duct. Drill a 16mm hole in about the centre of the sheet, 90mm from the bottom edge.

5. Coil the duct with the remaining locking edge to the outside and slip it inside the end cap and coupler to form a cylinder. Wrap the cylinder with three layers of duct tape to secure it. Cut 500mm and 100mm lengths of 12mm copper pipe and join them with epoxy. Slip the assembled pipe into the cylinder.

Reinstall the pipe and glue a 12 to 10mm reducer to the short pipe that exits through the side of the form. Hold the pipe in place with duct tape.

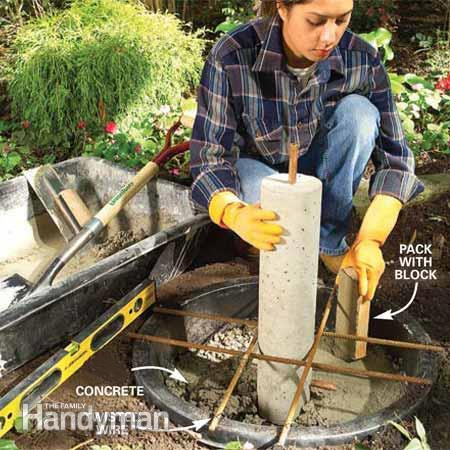

6. Coat the entire inside surface of both forms with a layer of spray lubricant is easy to apply. Mix concrete mix to form a stiff, not runny, batch. Fill the tall cylinder while holding the pipe in the centre. Tap the outside with a scrap of wood to settle the concrete and release trapped air.

Fill the foam-lined top half-full. Lay 10mm rebar bar in a weave pattern on top of the concrete. Continue adding concrete until it's flush to the top of the form.

7. Settle the concrete and remove trapped air by tapping the bottom of the form with a hammer. Add concrete if necessary to fill the form. Continue tapping and circling for about two minutes.

Let the concrete harden until the water on the surface has soaked in or evaporated and your thumb pressed into the surface just barely leaves an indentation. Then rub a block of wood in a circular motion over the surface to bring a layer of soupy cement and sand to the surface.

8. Smooth the soupy layer of cement with a steel trowel. Smoothing the top surface requires two steps: floating and troweling. Float the surface by rubbing the concrete in a circular motion with a block of wood until a thin layer of soupy cement covers the surface. Next, flatten and smooth the surface with a steel trowel. Let the concrete harden overnight. If you don't plan to assemble the fountain immediately, cover the column and wheel with plastic and store them in a shady spot until you're ready. Otherwise, keep the fountain running for at least a week to keep the concrete wet while it cures.

9. Remove the sheet metal screws and unwrap the concrete wheel. Carefully place the wheel upside down on the bucket and remove the plywood. Protect the top surface by placing strips of foam between the bucket and concrete. Grab the copper pipe with a locking pliers or pipe wrench and twist and pull to remove it from the concrete.

Remove the metal form from the tall cylinder.

GOOD TO KNOW

Wear long rubber gloves when you're working with concrete. Wet concrete can seriously burn bare skin.

10. Use a hacksaw or angle grinder to cut the rebar to length. Be very careful when you're working with the hardware cloth - the cut edges have razor-sharp points. Wear thick gloves and bend all cut edges down before you install the cover over the tub.

Don't cover the hardware cloth with stones until you've filled the tub with water and tested the pump.

11. Lay lengths of rebar over the plastic tub to create a square opening in the centre for the concrete column. Drill two small holes through the tub at the end of each rebar and secure the rebar with twists of wire. Leave the end of one rebar loose until the column is in position.

Dig a hole deep enough for the tub plus a 50mm deep layer of sand. Level the sand base and set the tub in place. Pack dirt around it to the bottom of the rim.

Set the column in place and use a level to make sure the sides are vertical and the flat area on top is level. Pour a 40mm layer of concrete into the bottom of liner to stabilize the column. Let concrete set overnight.

12. Cut a square of hardware cloth 100mm larger than the diameter of the tub and bend down a 50mm lip all around to form a mesh cover. Leave an extra couple of centimetres of mesh when you cut the opening shown and bend it around the rebar to hide the sharp edges.

Cut another small rectangle of hardware cloth to cover the opening. Connect the pump to the copper pipe with 16mm plastic tube and hose clamps.

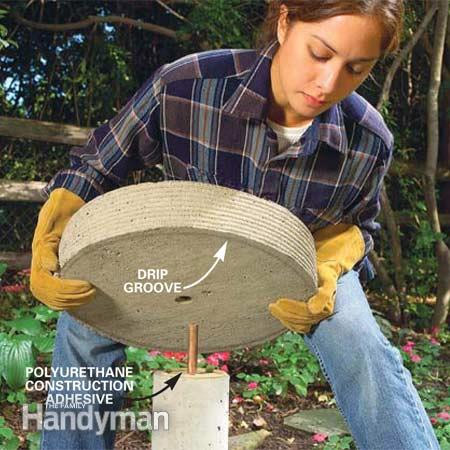

13. Place a bead of construction adhesive around the top of the column and lower the concrete wheel over the copper pipe. Check the top with a level and shim between the column and wheel if necessary to level the top surface.

Fountains Require a Little Maintenance

Keep the tub full of water. If it dries up while the pump is running, it will ruin the pump. Check the intake grate or screen on the pump occasionally and remove leaves and debris. If you live in a cold climate, drain the fountain in the fall. Then clean out the liner and store the pump inside for the winter.

handyman magazine