The Nature of Wood

Because wood is composed of variously shaped and arranged cell structures, it can be a challenging material to work with, so choose and use wood wisely.

04/09/2021

Wood is an organic material and a great deal of its appeal comes from the endless varieties of colour, texture and grain. But because wood is composed of variously shaped and arranged cell structures, it can be a challenging material to work with. Due to it's high cost as a valuable natural material - choose and use wood wisely.

This feature, is intended to shed some light on the complexities of selecting and working with wood. It begins with a discussion on the characteristics of wood, points out defects to avoid, explains how to properly work with wood in projects, and concludes with some advice on buying timber or wood.

SOFTWOODS AND HARDWOODS

The terms softwood or hardwood refer to the botanical origins of the wood. Softwoods come from cone-bearing trees, often with evergreen needle-like leaves, and the most common timbers in this group are nearly all conifers (Pine). Hardwoods are generally broad-leaved trees, either evergreen or deciduous. The term does not denote the relative hardness of the wood, although hardwoods are generally denser than softwoods.

TIMBER SELECTION

When selecting timber for a project a range of considerations will influence your selection, with cost being the primary factor. While fast growing Pine has become the most commonly used timber because of its relative cheapness other factors should be relevant:

- DURABILITY - A measure of a timber's resistance to attack from fungal decay and termites. All timbers exposed to moisture or used for construction or projects outdoors are at risk.

- HARDNESS - Different uses require timbers which have varying degrees of impact or crushing resistance. Resistance to bending might be another concern in the case of shelving or large construction projects.

- DENSITY - lf the weight of a finished project is of concern, selecting a wood with equal durability but less density will be a matter for consideration.

- ODOUR - Some timbers have a distinct aroma. Examples are Camphorwood, Cedar and Oregon Pine. On the other hand, some timbers have no odour and these are particularly suitable for food utensils.

- COSMETIC - A wood project that will be prominently displayed means you should give careful thought to Colour and Grain. When making your selection it is recommended that you view the various types of wood on offer.

AVOIDING DEFECTS

Choosing the right timber species will be the first step in your project and it is essential that you avoid defects. Problems can be grouped into natural defects and drying defects. The main natural defects being knots and gum veins. A knot makes no contribution to the overall strength of the wood - in fact a knot acts as if it were a hole. Furthermore, a knot causes a deviation of the grain (a cross grain effect) which often further reduces strength.

Gum veins are deposited by the tree like a shield to cover injuries caused by fire, insects or other causes. Veins, like knots, can be 'tight' or 'loose' and decrease the strength of your timber, not to mention that they are often considered to be unsightly.

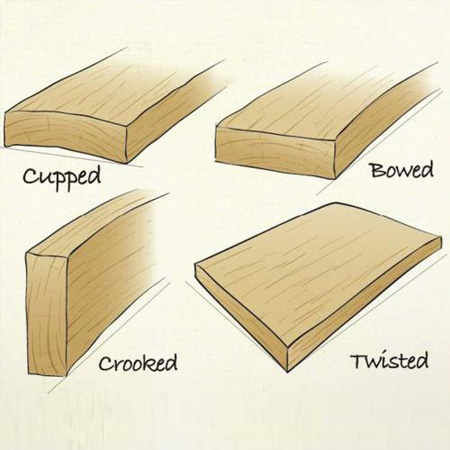

Drying defects result either from green timber being seasoned poorly, or from latent stresses present in the timber. Common problems include cupping, bowing and twisting, so always check with the timber merchant as to the grade of wood they supply. Select timber is chosen for its appearance and is destined to be used for furniture or cabinetry. Standard grade is structural timber and is not meant to be seen. There is usually a significant price difference between the two categories.

canadianwoodworking.com

TIMBER MOVEMENT

Timber is hygroscopic, meaning that it takes up and releases moisture depending on the humidity of the surrounding air. So even if your timber has been seasoned correctly, it will continue to expand and contract. Timber movement is complicated by the fact that it doesn't move equally in all directions. Changes in humidity hardly affect length, but shrinkage in width and thickness is appreciable.

CONDITIONING: lf possible, try to condition your wood before building your project by storing it for a few days in the same environment where the finished article will be. This helps the moisture content of the timber to match as closely as possible that of the surrounding air. This is particularly relevant if your project is to reside in a heated or air-conditioned room.

COATING: lt is advisable to coat both sides of your wood with a penetrating sealer. Not only will this slow the transfer of moisture from the timber to the air, and vice-versa, but it will prevent the warping that occurs when finish is applied to one face only.

DESIGN: When designing your own piece of furniture, be conscious of fastening one piece of wood cross-grain to another. There are correct ways of doing this, most commonly the technique of "slot-screwing" (fixing one component to another by using round-head screws, with washers, in elongated holes - don't glue!

MANUFACTURED MATERIALS: You can always avoid problems with humidity changes by using manufactured boards, such as plywood, particle board, or MDF. These manufactured board products have a balanced internal structure, and can be fixed without any concern for grain direction. However, there are some constraints: Particle board does not have great bending strength, so if you plan to use this material for shelves or similar, it will need to be supported at regular intervals or it will bow. Additionally these materials must be kept out of direct contact with moisture. Unless you are using exterior / marine grade plywood, they will deteriorate rapidly in high moisture areas.

When buying timber you will need to know the difference between nominal size and finished or actual size. The nominal size is the rough-sawn size of the timber, while the actual size is the planed size. Quite often the nominal size is quoted and the finished size is substantially smaller. The timber merchant will be able to tell you what size he finishes to, and it should be noted that different suppliers dress to slightly different sizes so it is wise to confirm measure the exact dimensions of your finished material before ordering. Click here for a list of timber and board suppliers across the country.