Joinery made easy with Kreg

The Kreg Pocket Hole Jig continues to be a must-have joinery jig for every woodworkers workshop. The K5 jig is the fifth generation of this impressive system and, while the pocket hole principle has remained unchanged, the new jig is a radical departure from the K4 pockethole jig. In this feature we look at the latest addition to the Kreg range of pockethole jigs.

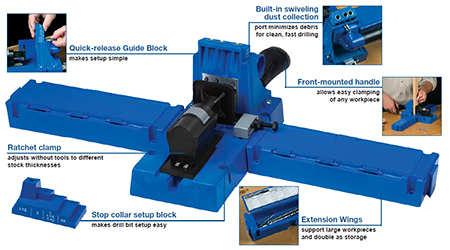

The K5 sports an automatic clamping system which compensates for tolerances in your board thickness. The dual extension wings not only provide useful storage but also act as a support for your larger work pieces, ensuring they always remain straight. Perhaps most importantly the new jig makes selecting the correct screw length and adjusting your jig easier than ever.

What’s in the Box?

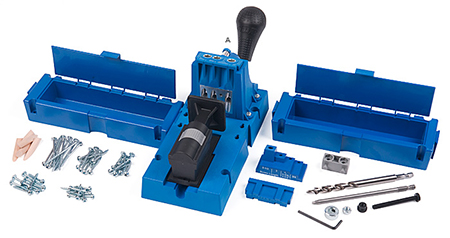

The set includes the K5 jig, the dual wing supports, and the new swivel action dust collection port. Of course the Kreg driver and drill bit, as well as a handful of screws are included. Additionally, the jig features a new adjustable and removable workpiece stop, for fast, accurate and repeatable pocket holes. The depth setting fixture is the most notable inclusion; this enables you to very accurately set the depth of your drill bit based on the screw you intend to use. No more over drilled holes.

What makes it unique?

Pocket hole joinery is one of the fastest methods of joining two pieces of timber together. The pocket hole is drilled into the side of your workpiece at a shallow angle. After that it is a simple matter of positioning your workpieces together and driving in a screw. That’s it.

Questions we are often asked:

Q: Do I have to use the Kreg screws?

A: The simple answer is yes. The Kreg screws have four unique and

essential characteristics. They are self-tapping, they have a flat head,

they have thread only half way up, and they have a square drive head.

All of this adds up to a strong pocket hole joint.

Q: Do I have to use glue?

A: We would always recommend using glue in your joints. It will help

prevent the joint from moving in the future, and also has the added

advantage of sealing the edge. And the nice thing is, with pocket hole

joinery you do not have to wait for the glue to dry.

Essential Accessories – Make your tool even better

Unlike the K4 Master System, the K5 Jig does not include the Face Clamp. This clamp is absolutely vital in pocket hole joinery. Because the pocket hole is at an angle, this pulls the two workpieces out of alignment when driving in the screw. To solve this problem, the two workpieces must be clamped together. This ensures that your joints will always remain flush.

The Right Angle Clamp is another extremely useful accessory. As its name implies, this clamp is used when producing right angle joints. One side of the clamp is shaped to fit into your pocket hole, which secures the pieces together and allows you to drive your screws into the other pocket holes. Once that is done, simply unclamp your workpiece and drive in your last screw.