TIG Welding in South Africa

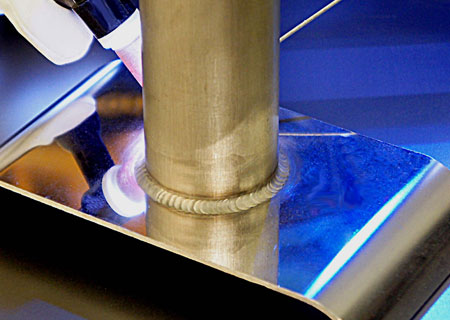

TIG welding is a popular welding process that produces high-quality welds. TIG welding is also known as gas tungsten arc welding.

29/10/2017

Gas tungsten arc welding, also known as tungsten inert gas (TIG) welding, is an arc welding process that uses a non-consumable tungsten electrode to produce the weld. The welder makes an arc between the base metal and the tungsten electrode. A constant-current welding power supply produces electrical energy, which is conducted across the arc through a column of highly ionized gas and metal vapours known as a plasma.

hotrod

The weld area and electrode is protected from oxidation or other atmospheric contamination by an inert shielding gas (argon or helium), and a filler metal is normally used.

The TIG process is commonly used to weld thin sections of stainless steel and non-ferrous metals such as aluminum, magnesium, and copper alloys. TIG welding allows greater control over the weld than other welding processes, allowing for stronger, higher quality welds.

wikipedia

The process of TIG welding can be used for substantially more metals than any other type of process. For this reason, it is used in the construction of spacecraft and airplanes in the aerospace industry, in auto manufacturing for its anti-corrosive properties, and is also widely employed in auto body repair shops. Drillly.com is a popular platform that reviews a number of TIG welders to find the best. You can check their review page out to find your best match.

Advantages of TIG welding

The welder has unsurpassed control over heat and amperage - with precision via a foot or thumb remote control switch - and since the TIG welder is thin, this further adds to the control a welder. As a result, TIG welding is good for projects where detailed designs or curves are required on the base metal.

Since the TIG welding torch uses low amperage, the process works well on thin pieces or metal. The combination of the low amperage and remote control switch allows welders to quickly switch from working on thin pieces of metal to thick ones, making TIG welding a versatile process. Since no fluxes are used and it’s possible to produce a low-profile weld bead, the weld is clean and free of slag.

Disadvantage of TIG welding

Because only a small area of space separates the arc of the flame from the base metal, TIG welding requires a high level of concentration and hand-eye coordination. Performing TIG welding requires skills and patience because the process can be time consuming, but this can be overcome with training and practice.

TIG welding as a hobby or career

TIG welding is a challenging, yet rewarding process and proper training opens up a host of promising careers. Here in South Africa, there are welding training programs that teach this technique. See Welder Training Centre (weldterstc.co.za) for more information on welding workshops, or do an online search for welding workshops in your region.

wikipedia

References:

https://en.wikipedia.org/wiki/Gas_tungsten_arc_welding

https://www.weldingschool.com/blog/welding/what-is-tig-welding/

http://www.hotrod.com/articles/tig-welding-101/